Bilayer tablets consist of two or more different layers compressed together to form a single tablet. Bilayer tablets are gaining popularity due to their ability to administer multiple active ingredients in one single dosage form. Patients prefer a simple dosing regimen rather than taking multiple different pills throughout the day. Bilayer tablets can help in administering multiple drugs each with a different release profile. This will help increase patient compliance and provide effective treatment.

Fixed-Dose Combination Therapy

Doctors often prescribe multiple drugs to patients suffering from severe diseases. Synergistic action by dual or multiple different drugs can provide greater efficacy or reduced side effects. The formulation for bilayer tablets can also be designed such that each active pharmaceutical ingredient (API) can have a different release profile. A popular example is CefloxCare, used to treat sexually transmitted diseases. Cefixime is released immediately to kill the harmful bacteria and ofloxacin has a delayed release to prevent further bacterial growth.

PrandiMet is also a fixed-dose combination, which contains metformin and repaglinide used to treat patients with diabetes. Metformin helps reduce the sugar absorption and storage in the liver from food and repaglinide induces more insulin secretion.

Bilayer Tablet Manufacturing Insights

Developing and manufacturing bilayer tablets require certain considerations as compared to normal, single-dose tablets:

- Tablet layers should be colored differently to be able to visually distinguish between the different medication layers to detect possible intermixing. Intermixing can negatively affect overall drug stability, lead to out-of-specification (OOS) dissolution results, and cause total batch failure.

- A clean separation of layers provides more aesthetic appeal and adds elegance to the tablet. Pharmaceutical elegance contributes to patient acceptability thus increasing patient compliance.

- The first layer must be able to withstand precompression and a second compression cycle without affecting overall tablet strength. This is achieved through the correct selection of plastic and brittle fracture undergoing excipients and suitable tablet binders.

- Each layer should have enough bonding strength at the interface and not laminate during coating or shipping.

- Tiny defects at the bilayer interface can be exacerbated during the coating process. If the formulation contains a modified-release coating, the drug release will be affected in-vivo and affect treatment.

- Both formulations should have good powder flow and the weight of each layer should be within acceptable limits. Variations to powder weights can affect the amount of drug delivered, leading to under- or overdosing of medication.

- Formulators should consider tablet size when developing bilayer tablets. Certain patient demographics have difficulty swallowing and developing tablets that are too bulky will decrease patient compliance.

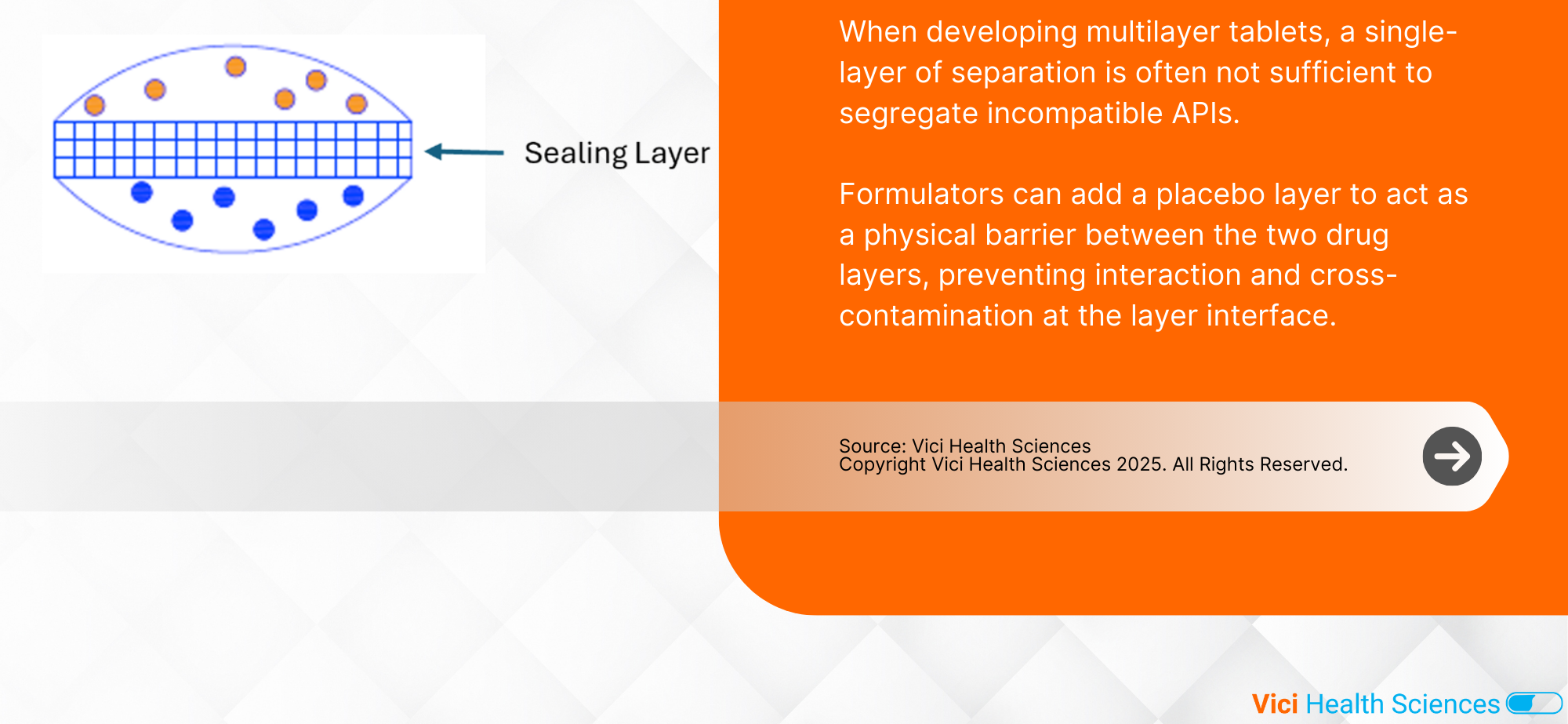

Multilayer Tablets

Multiple layers can be designed into a tablet when formulated correctly. Multilayer tablet medications like Requip-Modutab (ropinirole) prolonged-release tablets allow multiple drugs to be administered to a patient through a single, fixed-dose combination (FDC) tablet and decrease pill burden.

Another popular use of a multilayer tablet is to provide a zero-order release. This is achieved by the addition of two protective layers at the top and bottom ensuring that the API remains protected from its environment and is released at a constant rate. A constant release profile prevents API toxicity for drugs which have narrow therapeutic windows.

Precision Formulation Development for Market Success at Vici

As a CDMO specializing in formulation development, Vici can design, develop, and manufacture fixed-dose combination tablets for your drug development program. Our state-of-the-art R&D and compounding facility provides small-scale cGMP manufacturing for Phase I and Phase II clinical studies. Contact us today to speak with one of our experts and learn more about how Vici’s formulation expertise can help you accelerate your product to market.