Whether a dosage form must be sterile prior to administration depends on its route of administration. Parenteral products such as injectable formulations, ophthalmic formulations, otic formulations, and aqueous inhalation products must be sterile prior to use. Oral solid dosage (OSD) and oral liquids, topical, vaginal and anal suppositories on the other hand need not be sterile for use.

The subject of sterility often confuses even people who are involved in developing or prescribing drugs. Routes of administration where the dosage form release drug in parts of the body that contain its own microbiome do not need sterile formulations. Sterility is the complete absence of any microbial contaminant.

Ensuring sterility during manufacturing and storage

Manufacturing sterile dosage forms requires complete commitment to quality and cGMP compliance for sterile manufacturing and testing. There are two primary means of ensuring sterility. Aseptic manufacturing or terminal sterilization.

Aseptic manufacturing

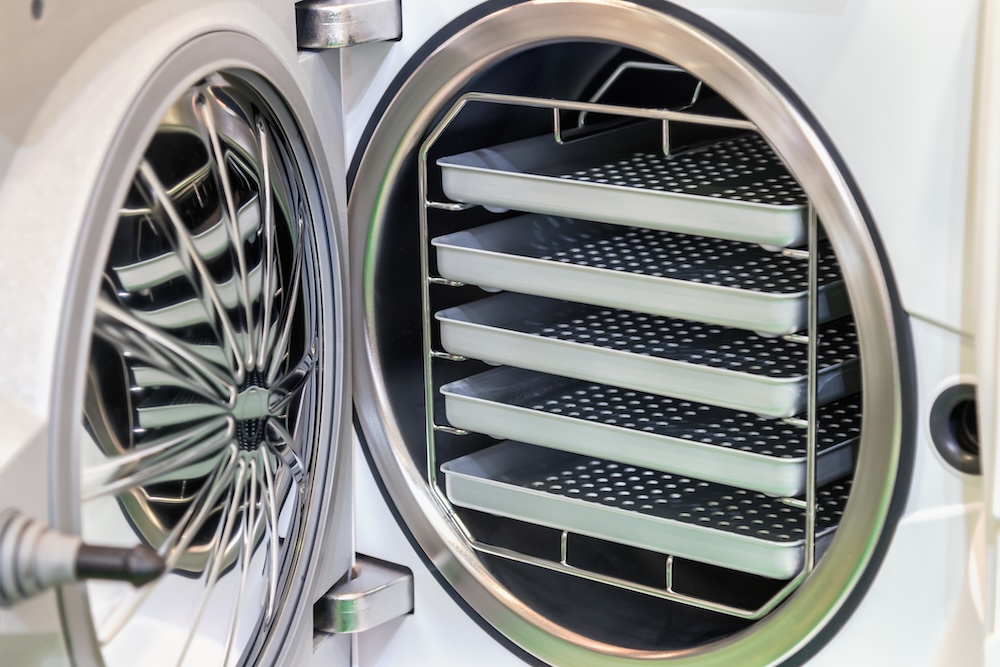

The product is manufactured under aseptic conditions to achieve a sterile product. Sterilization of raw ingredients or intermediate bulk material may be achieved by utilizing high temperature and pressure, as in an autoclave, or through sterile filtration where non-sterile ingredients in solution are passed through a sterilizing filter that has a small pore size. The use of heat must be thoroughly studied during formulation development to ensure that the drug substance does not degrade when exposed to steam in an autoclave. Likewise, filter compatibility studies are needed to ensure that drug substances and other ingredients are compatible with the filter material used. Filter validation studies are performed as part of the development of the manufacturing process.

Packaging components must be sourced sterile or sterilized prior to filling. Pre-sterilized packaging components may be expensive, leading to many CMOs opting for autoclaving vials and other packaging components to control cost for higher volume lower value products.

Terminal sterilization

A more elegant method for sterilization is terminal sterilization where the product is manufactured and packaged prior to sterilization. This is achieved by means of exposing the packaged product to radiation, heat, vaporized hydrogen peroxide, or ethylene oxide. The terminal sterilization process must be validated for each product since different ingredients and packaging components may behave differently over varying time intervals and different intensity of exposure. Additionally, the active ingredient or other ingredients may degrade with exposure to radiation, heat, or chemicals leading to failure to meet specifications. Sterilization studies must be thoroughly performed and validated during drug development.

Terminal sterilization is particularly useful for sterilizing complex formulations such as suspensions and semisolid ophthalmic formulations as they cannot be filtered or may be heat labile, thus excluding aseptic filling as an option.

Packaging selection and design for maintaining sterility

The packaging components selected during drug development play an important role in maintaining sterility over the life of the product. Packaging integrity testing must be performed to ensure that sterile products don’t leak leading to microbial contamination during storage.

Maintaining sterility during use by patients

Due to cost considerations for the patient, many injections, ophthalmic formulations, and otic formulations are formulated as multi-use vials or bottles. This means that the patient or provider repeatedly uses the vial or bottle prior to discarding the product. Such use may span many weeks. In such cases, the packaging components and the formulation play an important role in ensuring that the dosage formulation stays sterile during its approved use period. Self-sealing stoppers and the use of anti-microbial preservatives are techniques typically used by formulators for such multi-use vials and or bottles. Sterility testing must be performed as part of in-use stability testing for multi-use sterile products and in-use shelf life properly established.

Microbial considerations for non-sterile products

Oral formulations, semisolid topical formulations, vaginal delivery suppositories, or anal suppositories need not be sterile for safe use. Nevertheless, they must not contain dangerous pathogens such as Escherichia coli, Staphylococcus aureus, Pseudomonas, or Candida species depending on the route of administration. Manufacturing controls for non-sterile oral or topical products must be based on a risk-based evaluation of the formulation and manufacturing process. Special precautions must be used in selecting raw materials that are derived from natural sources. Equipment cleaning procedures and water treatment must adhere to established and approved standards. Aqueous formulations must include antimicrobial preservatives and antimicrobial efficacy testing, preservative assay, and microbial limit tests are performed during development, release testing, and stability testing based on risk assessment.

Your full-service CDMO partner

Proper consideration must be given to microbial contamination during formulation development and pharmaceutical product manufacturing. A properly developed formulation and manufacturing process will result in safe products for patients. At Vici, we fully understand the ins and outs of formulation development for sterile and nonsterile products and can help you navigate the complex world of formulation development and pharmaceutical manufacturing. Tell us about your project today!