Ophthalmic Formulation Development

Home » Formulation Development » Ophthalmic

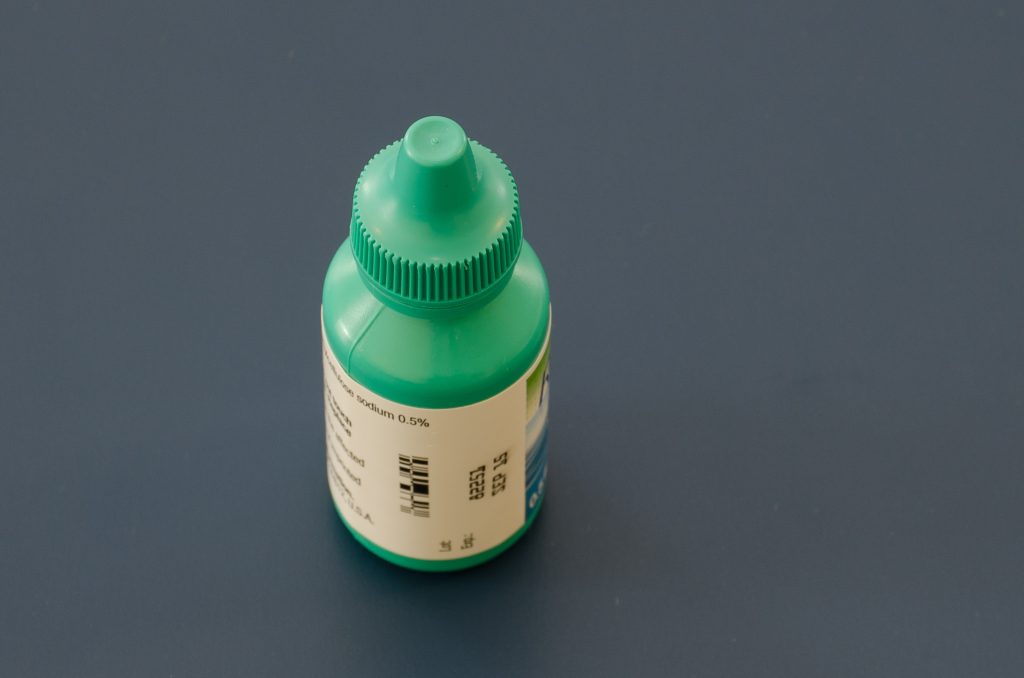

Ophthalmic dosage forms are designed to administer drug doses to the eye. Typically, this is done to treat infections, glaucoma, dry eye, or general inflammation. Ophthalmic solutions are the simplest form of ophthalmic formulations since it allows the drug to be fully solubilized into the volume of delivery fluid.

Ophthalmic Suspensions

Ophthalmic suspensions need to be carefully formulated to ensure that the drug particle size does not induce irritation in the eye. It is critical that each bottle provided to the patient contains the precise amount of drug, within tolerable limits, and that each drop of medicine retains the required uniformity. Development of ophthalmic suspension requires the use of viscosity enhancers, a careful balance of stabilizers and emulsifiers, and a thorough understanding of the material properties of the drug substance.

Once formulation development is complete, it is important to confirm that the selected manufacturing process properly meets the required product specifications. Sterilizing ophthalmic suspensions can be a complex undertaking due to the inability to perform sterile filtration. Autoclaving may not be feasible if the drug substance is not stable at high temperatures. Sterile drug substance (API) is typically used in combination with aseptic mixing and filling techniques to achieve product sterility. Terminal sterilization using radiation can also be employed for sterilizing ophthalmic suspensions.

Ophthalmic Gels and Ointments

Ophthalmic semisolid dosage forms that can be utilized when ophthalmic solutions are not feasible. Gels and ointments provide the benefit of having a longer duration of action as they tend to stay in the eye for an extended period of time due to their viscosity. A thorough understanding of the material and thermodynamic properties of semisolid drug delivery systems is needed to ensure that such products can be manufactured while maintaining quality and content uniformity for the patient with each application of the medication.

Critical Elements to Consider During Ophthalmic Product Development

- Achieving & Maintaining Product Sterility – the formulation, manufacturing process, and packaging components must all be carefully selected through experience and experimentation to ensure the product maintains sterility throughout manufacturing, distribution, and repeated patient use.

- Eye Irritation – suitable drug substance (API), inactive ingredients (excipient), and packaging components must be considered to ensure that particulates or chemical irritants do not negatively affect the product. Adequate test methods and control strategies must be developed and implemented per current US FDA regulations.

- Bioequivalence to Existing Reference Products – the development of generic (ANDA) or 505(b)(2) ophthalmic products require special considerations. FDA requirements mandate developers to demonstrate both qualitative and quantitative (Q1/Q2) similarity to reference products in order to be considered for approval. Additional requirements (often referred to as Q3 requirements) are needed for more complex ophthalmic formulations which may include matching particle size distribution, viscosity, crystal habit, and other higher order structural similarities.

We're Here to Help

Our industry experts at Vici Health Sciences can bring your product to market faster.

We provide both experience and expertise in the complex requirements for both generic ophthalmic (ANDA) and 505(b)(2) product development. Schedule a free consultation for a better understanding of the requirements, cost, and timeline for your projects.