Pharmaceutical Clinical Supply Manufacturing

Home » Clinical Supply Chain » Clinical Supply Manufacturing

Phase I Clinical Study Material Manufacturing

Vici can manufacture cGMP first-in-human clinical trial material for a variety of dosage forms including:

- Tablets

- Capsules

- Oral solutions

- Oral suspensions

- Powders or granules for reconstitution

- Topical creams

- Topical ointments

- Topical gels

- DEA-licensed for manufacturing and export to support foreign clinical studies

Phase I clinical trial material does not require large batch size. The cost of active ingredient (API) may be high, and multiple strengths are needed at this stage of the development program. Vici has the experience required to provide guidance on batch size selection and overall formulation and clinical strategy to save you time and money increasing the chances for successful outcomes. Vici utilizes API-sparing technologies and small-scale cGMP equipment to optimize batch size and reduce cost while manufacturing sufficient product to cover IND requirements, clinical study requirements, and stability requirements, and pass the savings on to you.

When it comes to early-stage drug development where CMC (chemistry, manufacturing, and controls) knowledge and requirements are still evolving, Vici is better suited to manufacture Phase I batches than operators who perform routine commercial manufacturing of fully developed commercial products.

In addition to batch manufacturing, Vici will also handle phase appropriate analytical method validation, IND related CMC and other regulatory documentation, raw material sourcing, batch release testing, and clinical trial material stability testing per FDA requirements.

Phase II Clinical Study Material Manufacturing

Vici can manufacture intermediate sized batches more suitable for Phase II clinical studies. Our cost will be lower than using a commercial sized CDMO or CMO who is more focused on large batch size manufacturing. At this stage of drug development, the formulation and analytical methods continue to evolve and are more advanced than that of first-in-human phase 1 studies but much less developed than what is needed for phase 3 studies. As experts in formulation development, Vici is perfectly suited to manufacture phase 2 clinical trial material quickly and for less money. We will also include formulation optimization studies needed, phase appropriate analytical qualification/validation, release testing, CMC updates to the IND, regulatory documentation and filing, release testing, and stability studies to support ongoing clinical studies. Vici can also develop matching placebo formulations for your clinical trials and manufacturing cGMP placebo batches.

We can manufacture phase 2 clinical trial material for all oral and topical including tablets, capsules, oral liquids, powders or granules, and topical creams, ointments, or gels.

Phase 3 Clinical Study Material Manufacturing

Vici offers phase 3 clinical trial material manufacturing services for the following dosage forms:

- Solid oral dosage forms including tablets and capsules

- Packaging in HDPE bottles

- Bilayer tablets

- Osmotic tablet technology for zero order release

- 100,000-1M doses per batch

- Granulation, drying, blending, compression, and tablet coating

- Functional or appearance coating

- Solvent coating for tablets

- Enteric-coated tablets

- Liquid oral dosage forms including solutions and suspensions

- Bottle and dosing cup for liquids

- Immediate-release and extended-release

- DEA Schedule II-V for Phase III and commercial supplies

Phase 3 clinical trial material batches will be manufactured at a 54,000 sq ft facility that has had a successful FDA audit history and is currently also manufacturing commercial batches of OSD and liquid dosage forms. Vici can offer manufacturing process validation and commercial batch manufacturing at the same facility making your transition from R&D to commercial manufacturing seamless.

The CMC requirements for phase 3 and registration batch manufacturing are quite extensive as the FDA expects the sponsor to use commercial-ready formulations, analytical methods, specifications, ingredients and manufacturing processes to manufacture pivotal phase 3 clinical trial material and stability batches to establish shelf life of commercially approved products. Being strong in formulation development and manufacturing process development and optimization, Vici’s scientists can perform the needed manufacturing process scale-up and optimization to ensure that your FDA filing is robust, and all CMC requirements are met by the time the phase 3 supplies are manufactured.

Manufactured in the USA

Our CDMO is based in Maryland, USA and all formulation development, analytical method development, clinical batch manufacturing, and commercial batch manufacturing occurs in the US. This is important for sponsors who are funded by SBIR grants, department of defense grants, or other government agencies that have requirements related to the percentage of grant funding that must be spent within the country.

Our Commitment to Quality

GMP manufacturing requires ensuring proper identity, strength, purity, and quality of each dose that may be used by a patient or given to a clinical study participant. Adhering to Quality by Design (QbD) principles, Vici designs formulations which meet pre-set quality standards. Quality is assured through careful, SOP-based control of raw materials supply chain, employee training, facility maintenance, equipment qualification, regular maintenance and calibration, formulation and test method development, batch manufacturing, release testing, and documentation.

Vici’s analytical testing lab develops, validates, and performs release testing on clinical supply material to issue a Certificate of Analysis (COA). Our analytical lab is governed by a strict SOP-driven quality system. All of our equipment undergoes routine preventive maintenance and calibration. Our HPLCs are 21 CFR Part 11 compliant. Vici follows good documentation practices and staff are trained in all SOPs. The lab system is overseen by the Quality Assurance (QA) group.

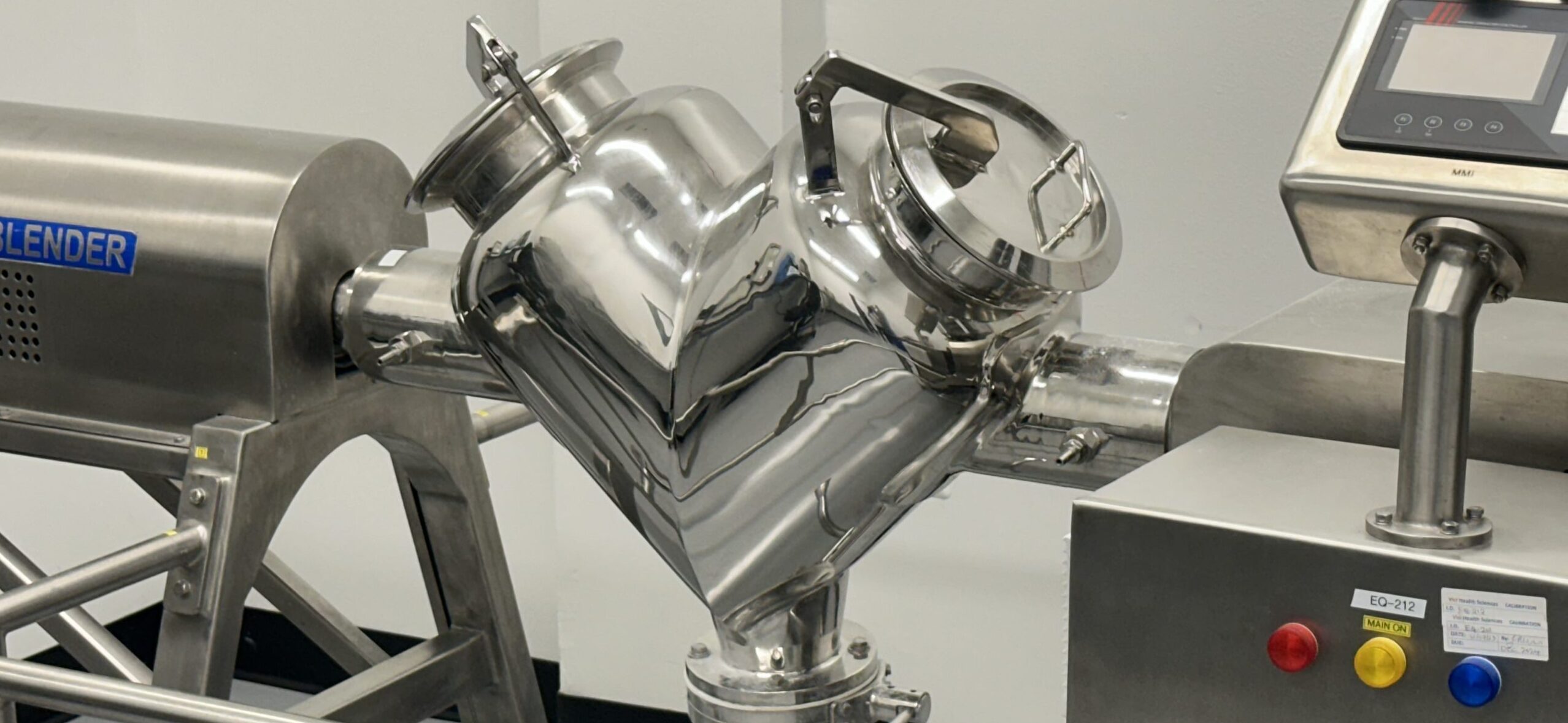

Vici operates four purpose-built formulation suites with state-of-the-art equipment for GMP batch manufacturing. Phase 3 clinical batches will be manufactured in an FDA inspected and approved site for seamless transition to commercial manufacturing.

Contact Us

Pharmaceutical Solutions for Product Development

From compounds to commercial production, we are the pharmaceutical product manufacturing partner you can rely on. Discover why Vici is the best CDMO for pharma production. Speak with one of our experts about your project today.