Assay Development & Validation

Home » Analytical Testing » ID & Assay

Identification (ID) testing is one of the most crucial elements of cGMP supply chain.

ID Testing ensures that the correct active ingredient is used in the correct product. Thus, ID testing is performed on both the drug substance and drug product. This testing is not required on stability samples to establish shelf life.

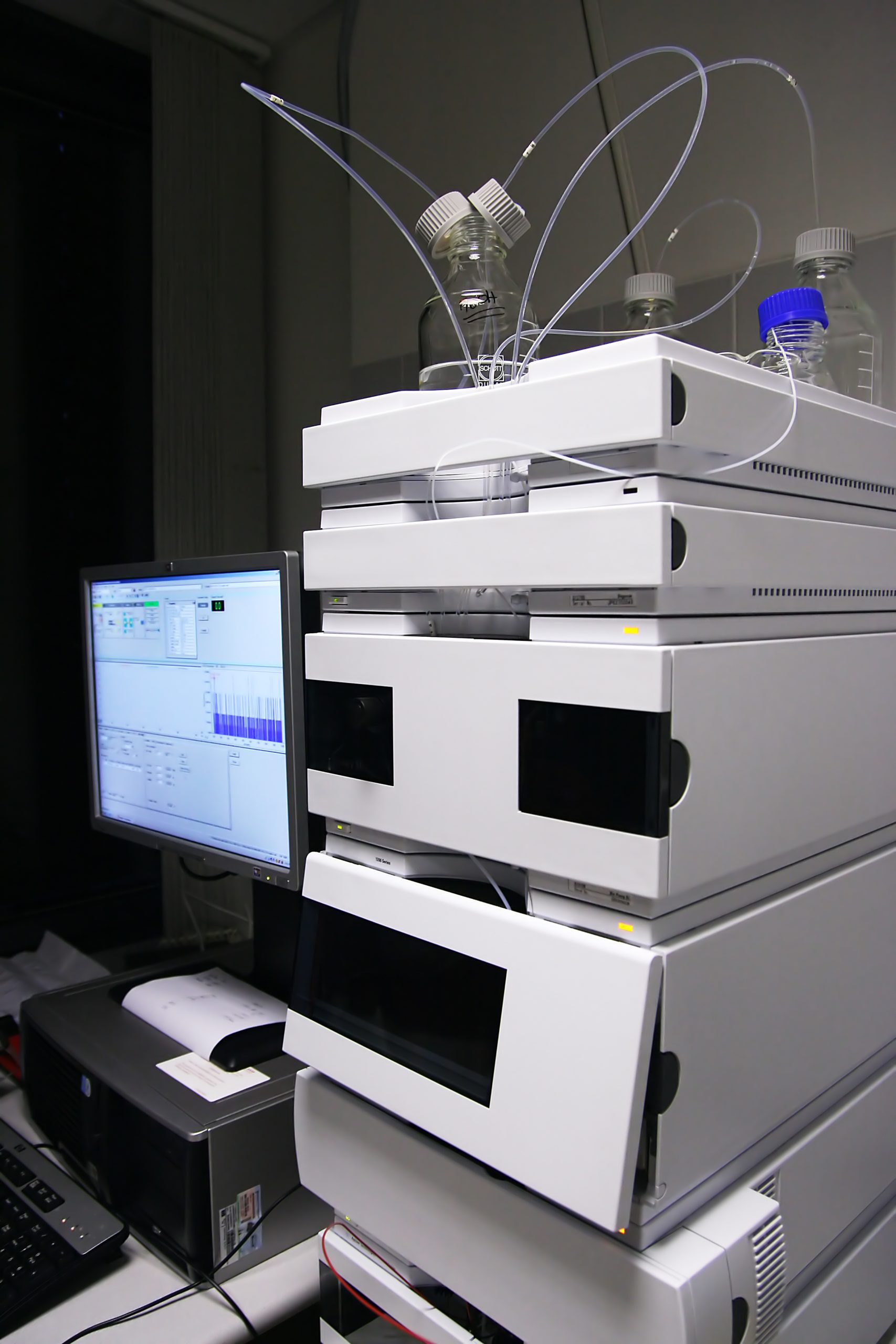

Techniques such as FTIR, NMR, MS, and HPLC-PDA can be used as ID tests for active ingredients. This is because all molecules have a unique structural signature that can be detected through analytical chemistry tests. Orthogonal techniques are required to confirm the ID of active ingredients in pharmaceutical products. The preferred method to test for known active ingredients is a High-Performance Liquid Chromatography (HPLC) equipped with a photodiode array (PDA) detector and comparing the peak retention time and spectral signature using a wavelength scan to establish analytical standards. At Vici Health Sciences, we utilize state-of-the-art Waters™ HPLC-PDA running Empower 3 to perform ID testing on active ingredients and finished products to ensure quality per cGMP/GLP standards. All testing data generated at our Quality Control (QC) labs are approved by our independent Quality Assurance (QA) department prior to generating a Certificate of Analysis (COA).

Potency Assay Testing

Vici develops stability-indicating potency assay methods, per FDA requirements, to support cGMP manufacturing and testing. Potency assay testing is performed on the active pharmaceutical ingredient (API) or drug substance, drug product, and special ingredients such as preservatives and other ingredients with a label claim. Vici utilizes state-of-the-art HPLCs to offer HPLC-based impurity and related substances method development, validation, and testing using the following:

- HPLC UV detectors

- HPLC PDA detectors (photo diode array)

- HPLC RI detectors (refractive index)

- Ion chromatography (Dionex system) to detect ions that do not have chromophores for UV detection

We also use ICH stability chambers to perform necessary product shelf-life studies and testing for both clinical trial material and commercial supplies.

Assay Method Development & Validation

Assay method development is typically based on compendial methods or methods provided by the drug substance vendor. If such methods are not available, Vici’s experts can develop de novo analytical methods.

Typically, specifications for assay are between 90-110% of the label claim for active ingredients. Products developed for the EU market often have tighter specifications. These specifications apply both during release testing and for stability tests performed for establishing shelf life. Failure to achieve these specifications will trigger Out Of Specification (OOS) investigations to determine root cause and remediation plans.

Drug Product Assay Method Development & Validation

Vici is experienced and has perfected the technique in developing reliable, accurate assay methods for pharmaceutical and dietary supplement products. For assay method development, the active ingredient must be fully extracted from the dosage form containing inactive ingredients, which can prove challenging for drug products containing extended-release excipients.

Assay methods must be stability-indicating for use in establishing shelf life. Forced degradation studies and the use of an HPLC equipped with a photodiode array (PDA) detector are utilized to determine HPLC peak purity as part of developing a stability-indicating assay method. At Vici, we can develop assay methods for both QC-release testing and stability studies to establish shelf life for your products.

Contact us today to see how we can help you with your analytical testing needs.

Contact Us

Pharmaceutical Solutions for Product Development

From compounds to commercial production, we are the pharmaceutical product manufacturing partner you can rely on. Discover why Vici is the best CDMO for pharma production. Speak with one of our experts about your project today.