Commercial Pharmaceutical Oral Solids Manufacturing

Home » Manufacturing » Commercial Pharmaceutical Oral Solids Manufacturing

Vici offers integrated pharmaceutical R&D and large-scale commercial manufacturing services for oral solid dosage (OSD) pharmaceutical products. Both R&D and commercial manufacturing operations are conveniently located in Maryland, USA.

Seamless Scale-up from R&D to Commercial Manufacturing

We can perform early-stage formulation development through process scale-up and commercial manufacturing with full regulatory filing support to provide a one-stop shop CDMO experience for our customers. Our highly qualified and trained technical and operations staff have years of experience developing and commercially manufacturing both NDA and ANDA tablet and capsule products for the US market.

The commercial manufacturing facility is 54,000 sq ft and located in Maryland. The plant is equipped with a variety of modern manufacturing and packaging equipment to meet your OSD manufacturing needs.

- Blenders, V-shell and double cone blenders ranging from 1 cubic ft through 75 cubic ft with a variety of options in between to cover a wide range of batch sizes for OSD to handle all your clinical supply and commercial product needs

- Granulators, high shear wet granulators and tray dryers

- A variety of milling and sieving equipment including Comil, Fitzmill, and Sweco

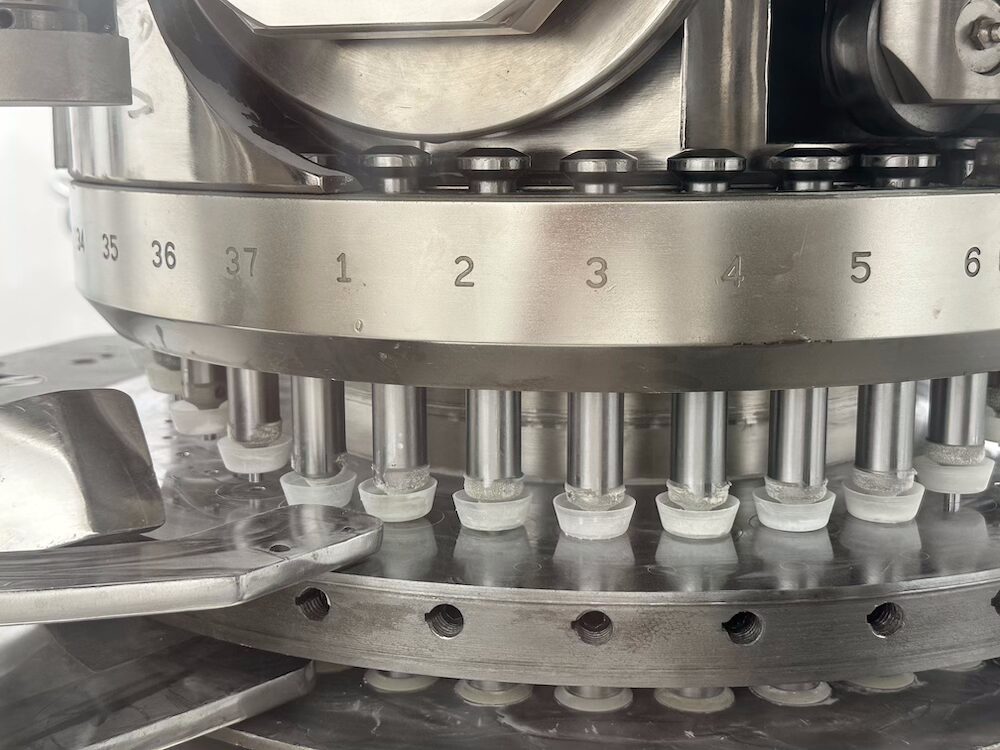

- Tablet presses, a variety of tablet presses ranging from single-station, 16-station, and 55-statoin high speed instrumented single layer and bilayer tablet presses

- De-dusters and metal detectors

- Tablet coaters include explosion proof models for solvent coating that can handle 200 grams to 100 kg batch size

- Capsule fillers

- Powder in bottles and pouch filling machines

- A full packaging line updated for serialization capability

FDA Approved, cGMP Manufacturing

The commercial manufacturing plant has a successful audit history with the US FDA and currently manufactures prescription branded and generic products for the US market. The plant operates under a robust quality management system to ensure cGMP compliance across all spheres of activity including sourcing, the warehouse, manufacturing, packaging, and QC (quality control) testing. An independent and experienced quality assurance (QA) team oversees all cGMP operations to ensure full compliance.

The QC laboratory, led and staffed by highly qualified chemists, is equipped with Waters HPLC running the latest version of Empower and is equipped with UPLCs for rapid throughput. Our QC lab is equipped with:

- Dissolution baths with auto samplers

- GCs

- Atomic absorption spectra capability

- Full range of ICH stability chambers for stability testing and establishing shelf life for pharmaceutical products

Our analytical chemistry team can fully develop, validate, and transfer all needed drug substance, excipient, and drug product release testing and stability testing methods.

Contact Us

Pharmaceutical Solutions for Product Development

From compounds to commercial production, we are the pharmaceutical product manufacturing partner you can rely on. Discover why Vici is the best CDMO for pharmaceutical production. Speak with one of our experts about your project today.